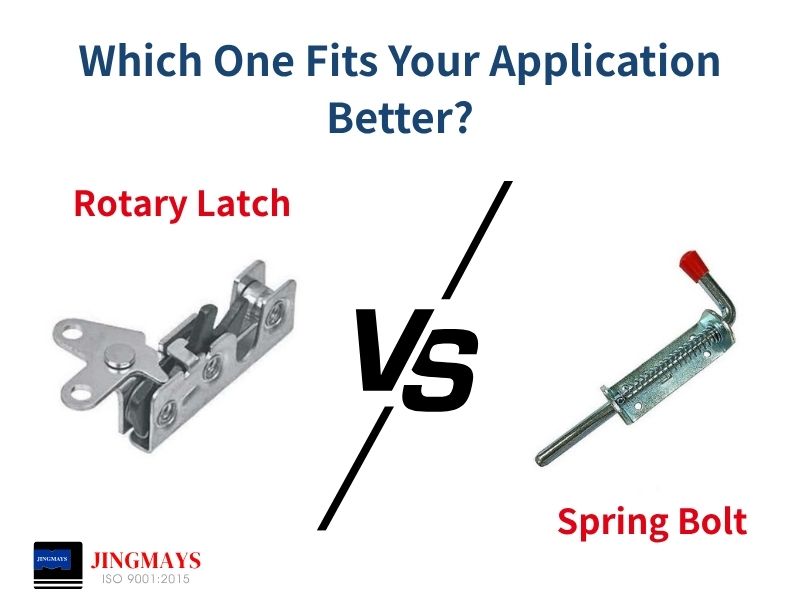

Spring Bolt vs. Rotary Latch: Which One Fits Your Application Better?

When it comes to securing doors, panels, and enclosures in industrial and vehicle settings, both spring bolts and rotary latches offer durable, high-performance solutions—but each has its own advantages. At Jingmays Industrial Co., Ltd., we manufacture both types to meet diverse customer requirements. So which one should you choose?

Let’s compare their features, use cases, and key differences to help you make the best decision.

Understanding the Spring Bolt

A Spring Bolt is a mechanical fastener that uses internal spring tension to slide into a locked position. Once pushed into place, it remains locked until pulled back manually—no external power or electronics required. It’s favored for its ease of use, compact size, and quick-release action.

Common Applications:

- Utility cabinets

- Trailer doors

- Service compartments

- Agricultural machinery

- Storage containers

Key Features:

- Single-hand operation – fast and intuitive

- Made from zinc-plated steel – corrosion-resistant and impact-resistant

- Compact design – perfect for limited space areas

- Rustproof finish – ideal for outdoor and marine use

Understanding the Rotary Latch

The Rotary Latch is a more complex locking system that utilizes a rotating jaw mechanism to catch and hold a striker. Designed to provide secure retention and vibration resistance, it’s a top choice for heavy-duty enclosures or vehicle panels that experience frequent movement.

Common Applications:

- Delivery truck hatches

- Electrical or battery compartments

- HVAC access doors

- Trailer side panels

- Heavy machinery housings

Key Features:

- Hidden mounting – provides cleaner aesthetics and enhanced security

- High load capacity – excellent for large or heavy panels

- Shock- and vibration-resistant – ideal for mobile applications

- Compatible with remote cable release – upgradeable to keyless or interior-access controls

Side-by-Side Comparison

| Feature | Spring Bolt | Rotary Latch |

|---|---|---|

| Locking Mechanism | Spring-loaded pin | Rotating jaw/pawl mechanism with striker |

| Ease of Use | Very simple; push to lock, pull to release | Requires alignment and sometimes remote actuation |

| Security Level | Moderate, for general-purpose use | High, resistant to prying, impact, and vibration |

| Installation Complexity | Easy; surface-mountable or weld-on | Moderate; striker and latch must align precisely |

| Best Use Case | Quick-access doors or compartments | High-security, mobile or heavy-duty enclosures |

| Material at Jingmays | Zinc-plated steel, rust-resistant | High-grade steel and engineered plastics |

Material & Durability: Built for Tough Conditions

At Jingmays, both product lines are built to meet industrial-grade demands:

- Spring Bolts: Made of steel with zinc plating, these bolts offer excellent impact resistance, weather resistance, and smooth operation in all climates.

- Rotary Latches: Designed with reinforced steel bodies and precision-molded internal components, they provide long-lasting performance, even under continuous vibration or harsh mechanical stress.

Installation: Simplicity vs. Precision

Spring bolts are often chosen for their plug-and-play nature—they’re easy to mount, either by bolts or welds, and require minimal alignment. Rotary latches, on the other hand, demand precise striker alignment but offer enhanced security once installed.

Need custom mounting brackets? Jingmays offers OEM/ODM customization to match your installation needs precisely.

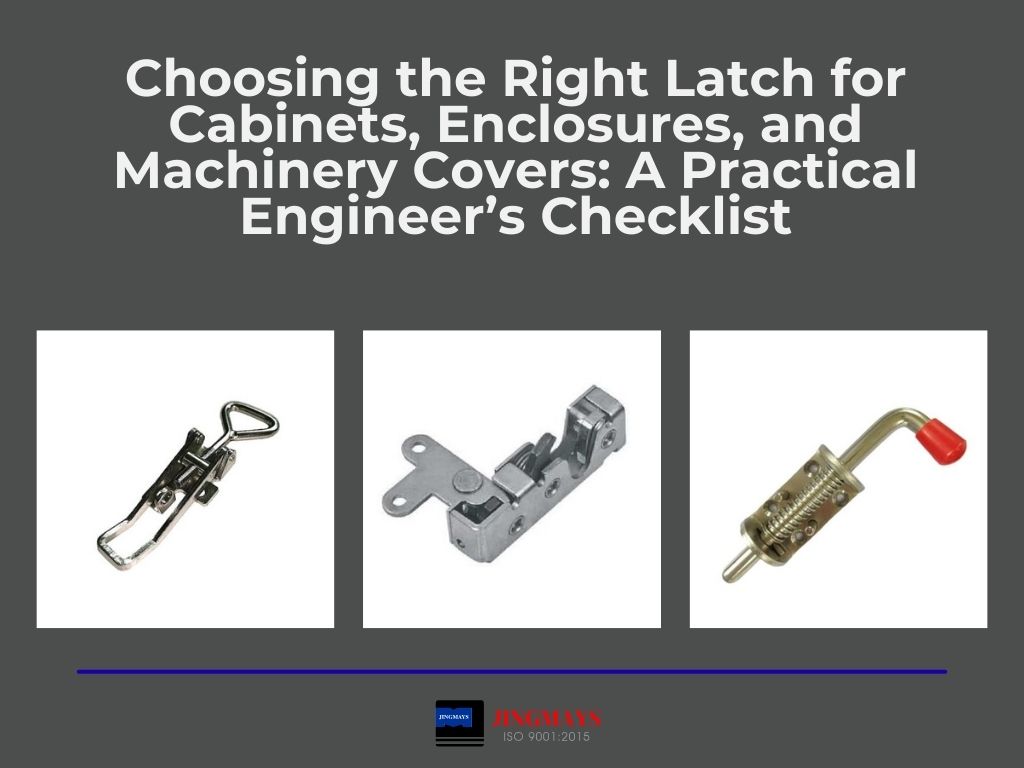

Industry Applications: Matching the Right Tool to the Job

| Industry | Recommended Locking Mechanism | Reason |

|---|---|---|

| Logistics/Trucking | Rotary Latch | Handles vibration and provides high retention |

| Agriculture | Spring Bolt | Quick access to compartments and ease of maintenance |

| Marine | Spring Bolt | Rust-resistant for exposed environments |

| Construction | Both | Choose based on required load capacity and access speed |

| Industrial Enclosures | Rotary Latch | Hidden design and high security |

Choose the Right Locking Mechanism with Jingmays

Whether your priority is fast operation, security, or durability, both spring bolts and rotary latches offer reliable solutions when selected properly.

At Jingmays Industrial Co., Ltd., we manufacture:

- Spring Bolts that combine performance, simplicity, and corrosion resistance

- Rotary Latches that deliver tamper-proof performance and vibration resistance in mobile environments

All products are manufactured under strict quality control standards and are available in various sizes, finishes, and mounting styles.

Contact Us to Find the Right Fit

Still unsure which option suits your application? Let our experts guide you. Whether you're designing a new product or upgrading an existing system, Jingmays Industrial Co., Ltd. is your trusted source for high-quality industrial hardware solutions.

We offer custom OEM/ODM manufacturing, technical consultation, and fast delivery for clients worldwide.

Contact us today to discuss your project or request a product sample!